When conducting experiments in 96-well plates, selecting the correct type of plate is crucial for achieving reliable results. The decision between using a standard 96 well plate or a deep well 96-well plate can significantly impact the efficiency of your experiments. While both plates are commonly used in laboratory settings, they serve different purposes based on their size, volume, and intended application.

Understanding the differences between standard and deep well plates will help you avoid errors in your research, save time, and optimize your experiments. This guide will provide an in-depth comparison of volume, dimensions, use cases, and practical recommendations for when to choose each type of plate for various laboratory tasks.

What Are Microplates? Overview & Standard Formats

A microplate, also known as a microtiter plate or multiwell plate, is a flat plate with multiple wells arranged in a regular grid, commonly used in laboratory applications like sample preparation, screening, assays, and reactions. They come in various sizes, but the most widely used is the 96-well plate, which has 8 rows and 12 columns.

Standard Formats of Microplates

Microplates are standardized based on their well count and dimensions. While 96-well plates layout are the most common, you may also come across 384-well or 1536-well plates depending on the scale of your experiment. For our discussion, we’ll focus on the 96-well plate format, which is the most prevalent in laboratory settings.

Microplates are typically classified based on:

- The number of wells: 96-well, 384-well, or 1536-well plates.

- Well shape: Flat-bottom, round-bottom, U-bottom, and V-bottom.

- Material: Plates can be made of different materials such as polystyrene (PS) for optical clarity (important for assays involving absorption or fluorescence) or polypropylene (PP) for its durability and resistance to chemicals.

For most experiments, the 96-well plate provides a balanced solution between sample volume and throughput. The decision between using a standard or deep well 96-well plate depends on the specific needs of your experiment.

Standard 96-Well Plates: Features, Volume & Typical Uses

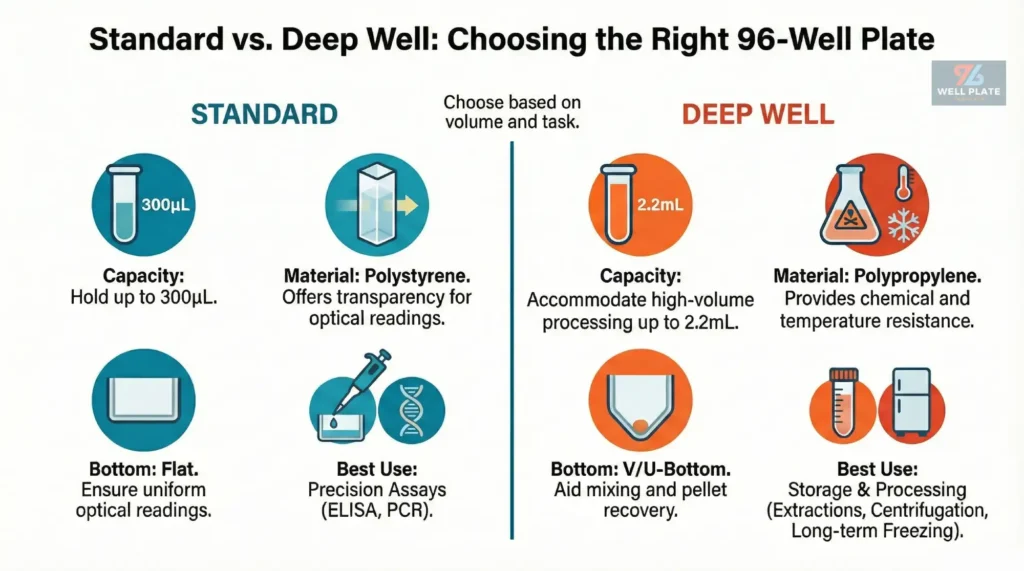

A standard 96-well plate is a laboratory tool used to perform assays and reactions with small volumes of reagents and samples. The plate typically has a well volume capacity of 100 to 300 µL, making it ideal for applications that do not require large volumes of liquid.

The wells in standard 96-well plates are generally flat-bottomed, ensuring even distribution of liquids and facilitating uniform optical readings in assays. Plates are commonly made from polystyrene (PS), which allows for precise observation and reading of absorbance or fluorescence.

Typical Uses

Standard 96-well plates are used in various laboratory assays where small volumes are required. These plates are popular for:

- ELISA assays: Measuring enzyme-linked reactions.

- PCR: Performing DNA amplification in a small volume.

- Cell culture assays: Growing cells for short-term studies.

- Fluorescence-based assays: Measuring the interaction of compounds with fluorescent dyes.

The standard 96-well plates offer a cost-effective solution for these applications because they require minimal reagents, reducing overall costs, especially for high-throughput screening or routine assays.

Why Choose a Standard 96-Well Plate?

A standard 96-well plate is most suitable when:

- You require small sample volumes for assays.

- You are performing high-throughput screening and need to process multiple samples in a relatively short amount of time.

- Your experiment involves optical measurements, such as absorbance or fluorescence readings, where clarity and transparency are key.

96-Well Deep Well Plates: What Makes Them Different?

What is a Deep Well Plate?

A 96-well deep well plate is a variation of the standard 96-well plate, with deeper wells that allow for larger volumes of liquid to be used. The primary difference lies in the well depth, which enables these plates to hold more liquid per well, often up to 2 mL or more, depending on the manufacturer.

The deeper wells in these plates are designed to accommodate a range of applications, such as sample storage, reagent preparation, and high-volume sample processing. The bottom of the wells is often round, V-shaped, or conical, allowing for easier mixing, centrifugation, and pellet formation.

Volume & Dimensions of Deep Well Plates

The volume capacity of a deep well plate is substantially higher than that of a standard 96-well plate. Typically, deep well plates can hold 2 mL of liquid per well, making them ideal for experiments that require larger volumes, such as DNA/RNA extractions or protein purification.

Here are some general dimensions and features of a 96-well deep well plate:

- Well volume: Typically ranges from 1.5 mL to 2.2 mL per well.

- Well shape: Most deep well plates feature round-bottom, V-bottom, or U-bottom wells, which allow for better liquid handling, mixing, and pellet formation.

- Material: Deep well plates are often made from polypropylene (PP), which is highly resistant to chemicals and temperature extremes, making them ideal for storage and long-term sample preservation.

Typical Uses of Deep Well Plates

Deep well plates are used in experiments where a larger volume of samples or reagents is required. They are also essential for:

- Sample storage: Storing biological samples, especially in freezing conditions.

- Large-volume reagent handling: Preparing large quantities of reagents or compounds in liquid form.

- DNA/RNA extractions: Using larger volumes to process biological materials.

- Cell culture: For experiments that require larger volumes of media or high-density cultures.

Deep well plates are often preferred in high-throughput sample processing, where larger volumes of liquid need to be handled or stored for future use.

When Should You Choose a Deep Well Plate?

- If your experiment requires larger volumes (1 mL or more) for sample prep, extraction, or storage, a deep well plate is the better choice.

- Long-term storage or handling of bulk quantities of reagents (e.g., for sample pooling or cell stock storage) is best suited to deep-well plates.

- If your experiment involves processes such as centrifugation, in which liquids need to be collected and pelleted, deep-well plates with round or V-bottom wells are ideal for ensuring effective liquid recovery.

Key Differences Between Standard and Deep Well 96-Well Plates

| Feature | Standard 96-Well Plate | Deep Well 96-Well Plate |

| Well Volume | 100–300 µL per well | 1.5 mL to 2.2 mL per well |

| Well Shape | Flat-bottom (for optical clarity) | Round-bottom, V-bottom, U-bottom |

| Material | Polystyrene (PS) | Polypropylene (PP) for durability |

| Typical Use | ELISA, PCR, small-scale assays | Sample storage, extraction, reagent prep |

| Plate Height | Lower profile, easier to handle | Taller profile, more liquid handling capacity |

| Best for | Small-volume assays, high-throughput screening | Sample storage, large-volume reactions, centrifugation |

When to Use a Standard 96-Well Plate vs When to Choose a Deep Well Plate?

Choosing the right plate for your experiment is essential for optimizing efficiency, reducing errors, and ensuring the best outcomes. Whether you are working with small sample volumes for assay testing or need to handle larger volumes for storage or extraction, selecting the correct type of 96-well plate can make a significant difference.

When to Choose a Standard 96-Well Plate

Standard 96-well plates are ideal for assays, screenings, and experiments that require smaller volumes and are focused on optical measurements. These plates are commonly used in laboratories due to their low reagent consumption and high compatibility with automated systems. Here are the scenarios when you should opt for a standard 96-well plate:

For Small Volume Assays:

If you are working with assays such as ELISA, PCR, or fluorescence-based assays, standard 96-well plates are the best choice. These assays require relatively small volumes (usually between 100 µL to 300 µL), making standard plates perfect due to their low reagent needs and efficient handling.

When High-Throughput Screening is Needed:

If you’re conducting high-throughput experiments where numerous samples need to be processed quickly, standard plates are often the preferred option. Their compact design and compatibility with automated liquid handling systems enable rapid processing, which is crucial for large-scale screening or sample processing.

For Optical Measurement Compatibility:

Standard 96-well plates are often made of polystyrene (PS), which offers superior optical clarity, ideal for assays that require absorbance, fluorescence, or luminescence readings. If your experiment involves optical measurements, the flat-bottomed design of standard plates enables accurate readings without interference.

When Speed and Cost Efficiency Matter:

Standard 96-well plates are ideal when time and budget constraints are factors. Their smaller well volumes reduce reagent costs and help process experiments more quickly. They are widely available and can be used across many types of assays, making them the default choice for many laboratories.

When to Choose a Deep Well Plate

In contrast to the standard 96-well plate, deep well plates are designed for experiments that require larger liquid volumes, better mixing, and enhanced storage capabilities. Here are the specific situations when you should use a deep well plate:

For Sample Storage:

If you need to store biological samples, reagents, or chemical compounds for an extended period, deep-well plates are the right choice. The larger well volume is ideal for storing samples in freezers or refrigerators, particularly for DNA/RNA extraction, cell culture, and protein storage. Additionally, the polypropylene (PP) material used for deep well plates is more resistant to chemicals and temperature fluctuations, making it ideal for long-term storage.

For Large-Volume Reagent Handling:

When your experiment requires preparing bulk quantities of reagents or mixing large volumes of solutions for downstream processing, deep-well plates provide greater capacity for these tasks. For example, they are commonly used for preparing large volumes of PCR reagents, stock solutions, or reaction buffers.

For Centrifugation and Mixing:

Deep well plates are also helpful when your experiment involves centrifugation, mixing, or pellet formation. The round or conical well bottoms allow for adequate mixing and the recovery of small volumes of liquid after centrifugation, making deep well plates an excellent choice for sample preparation, such as extracting proteins or processing cell lysates.

When Working with High-Volume Sample Pools:

If you’re handling sample pooling, in which you need to mix multiple individual samples into a larger volume, deep-well plates are ideal. The increased well depth allows for higher volumes, reducing the need for various plates and optimizing workflow efficiency in high-throughput setups.

For Long-Term Sample Preprocessing:

In research applications such as drug discovery, biobanking, or protein purification, deep-well plates are often used for long-term sample processing. Their larger well volume accommodates a broader range of sample volumes, allowing for bulk mixing, incubation, and storage during complex experiments.

Practical Tips: How to Use Each Plate Type Effectively

Now that you have an understanding of the differences between standard 96-well plates and deep well plates, it’s essential to consider how to use each type effectively in the lab. Below are practical tips and best practices to ensure you get the most out of each plate type, whether you’re working with a standard 96-well plate for small-volume assays or a deep well plate for sample storage or large-volume mixing.

Practical Tips for Using Standard 96-Well Plates

Choose the Right Well Shape for Your Assay:

Standard 96-well plates typically have flat-bottom wells, which are ideal for optical measurements like absorbance, fluorescence, or luminescence. If your assay involves optical readings, be sure to choose a flat-bottom plate to ensure accurate, consistent readings.

Optimize Sample Volume:

Standard 96-well plates are best used for small-volume assays. Typically, the wells are designed to hold between 100 µL and 300 µL of liquid. Always ensure that the well volumes are within the recommended range for your assay. Using too little liquid may lead to inaccurate results, while overfilling can cause spillage or interference with other wells.

Use Sealing Films:

To minimize evaporation and prevent cross-contamination during incubations or assays, it’s recommended to use adhesive sealing films. These films provide a tight seal, preventing sample loss, especially in assays involving prolonged incubation times, such as PCR.

Ensure Plate Compatibility with Readers:

When using standard 96-well plates, ensure the plate reader or detection system is compatible with the well design and material. Polystyrene (PS) is commonly used for optical assays, but some readers may require specific plates for optimal readings. Always check your equipment’s specifications to avoid issues.

Regularly Calibrate Pipettes:

For accurate results, it’s crucial to use well-calibrated pipettes when dispensing small volumes into standard 96-well plates. Inconsistent pipetting can lead to significant errors, especially in assays that rely on precise sample volumes.

Practical Tips for Using Deep Well Plates

Consider Plate Material:

Most deep-well plates are made from polypropylene (PP), which is chemical-resistant and durable, making it ideal for storing samples and handling solvents or other harsh chemicals. If your experiment involves harsh reagents, high temperatures, or freezing, polypropylene deep well plates will withstand these conditions better than standard polystyrene plates.

Use Appropriate Well Bottom Shapes:

Deep well plates often come with round, V-shaped, or U-shaped well bottoms, which are designed to facilitate mixing and centrifugation. If you need to pellet a sample or mix liquids thoroughly, choose a round or V-bottom deep-well plate to improve the efficiency of these processes.

Ensure Adequate Mixing and Pipetting:

Due to the larger well volume, deep-well plates may require more effort when mixing or pipetting. You might need a multichannel pipette or an automated liquid handler to fill and transfer liquids into deep-well plates efficiently. Magnetic stirrers or vortex mixers can also help achieve even distribution of reagents in the deep wells.

Sealing and Storing Samples:

For deep-well plates used for sample storage, it’s critical to seal the wells properly. Sealing mats or pierceable seals are often used to protect samples from contamination and evaporation during long-term storage, particularly when samples are stored at low temperatures in freezers or refrigerators.

Handling and Centrifugation:

Deep-well plates are commonly used for processes such as centrifugation and pellet formation. If your protocol involves these techniques, be sure to check that your plate is compatible with the centrifuge rotor and that the material can withstand the required g-forces without cracking or leaking. Also, ensure that the well design supports easy recovery of pellets or supernatant after centrifugation.

Use for Bulk Reagent Handling:

When preparing large volumes of reagents or chemical compounds, deep-well plates provide a high-capacity for mixing and storing reagents. For example, they are excellent for preparing large reaction buffers or stock solutions that will be used across multiple experiments. Using deep well plates reduces the need for multiple containers and helps centralize your preparation process.

FAQs

Can I use deep well plates for ELISA or fluorescence assays?

While deep-well plates can be used for a variety of assays, they are not ideal for optical measurements such as ELISA or fluorescence because they typically have lower optical clarity than standard 96-well plates. For optical-based assays, a standard 96-well plate with flat-bottom wells is preferred.

When should I use a deep well plate for sample storage or DNA/RNA extraction?

Deep well plates are excellent for sample storage because their larger wells provide more space for storing biological materials, especially when working with larger sample volumes or for long-term storage. They are also ideal for DNA/RNA extractions when larger volumes of reagents are required.

Are deep well plates compatible with standard plate readers?

Deep well plates may not be compatible with all plate readers, especially those designed for optical measurements, as the increased depth can interfere with light penetration. It’s essential to check your plate reader’s specifications to ensure compatibility before using deep well plates for optical assays.

Can I reuse deep well plates like standard plates?

Yes, deep-well plates can be reused, but cleaning and sterilization procedures must be followed carefully, especially if you’re using them for sample storage or reagent preparation. Some deep well plates may be designed for single-use only, so be sure to check the manufacturer’s recommendations.

Final Thoughts & Recommendations

Choosing between standard 96-well plates and deep-well 96-well plates depends on your experiment’s volume, assay type, and processing needs. Standard plates are ideal for small-volume assays, high-throughput screening, and optical measurements like ELISA and PCR. In contrast, deep-well plates are best for handling, storing, and mixing large volumes, making them suitable for DNA/RNA extractions and reagent preparation. By understanding these differences, you can select the right plate to ensure efficient and accurate results.