Well plates, also known as microplates or multiwell plates, are essential tools in laboratories, enabling researchers to conduct high-throughput experiments, analyze multiple samples at once, and streamline processes like cell culture, protein assays, PCR, and sample storage. With their standardized format, well plates are compatible with a wide range of laboratory instruments, including automated liquid handlers, plate readers, and thermal cyclers, making them versatile and indispensable in research settings.

Understanding the different types of well plates and their applications is crucial for optimizing experiments, saving reagents, and ensuring accurate results. In this guide, we will explore the primary uses of well plates across various disciplines, focusing on cell culture, ELISA, PCR, screening, and sample storage.

What Are Well Plates?

A well plate, also called a microplate or multiwell plate, is a flat plate with multiple wells arranged in a grid pattern, typically used to hold liquids for various assays and experiments. The most common format is the 96-well plate, which has 8 rows and 12 columns, although other configurations, such as 384-well and 1536-well plates, are also available for high-throughput applications.

These plates come in various materials and are well-designed for the intended application. For example, polystyrene (PS) is commonly used for optical assays because of its optical clarity, while polypropylene (PP) is used for chemical stability and sample storage.

Plate Materials and Well-Bottom Shapes

- Polystyrene (PS): A Transparent material, commonly used for optical assays like ELISA and fluorescence because of its clarity. PS plates are ideal for applications that involve reading light through the wells.

- Polypropylene (PP): More chemical-resistant and heat-resistant, ideal for long-term sample storage and use in harsh chemical environments. PP is often used in deep-well plates for larger volumes.

- Well Bottom Shapes: Well plates are designed with various bottom shapes to suit different needs:

- Flat-bottom: Best for optical measurements, such as absorbance or fluorescence readings, because the flat surface provides uniform light passage.

- Round, V, or U-bottom: These shapes facilitate centrifugation, mixing, or pellet formation, making them ideal for applications like sample storage or extraction.

Standardization and Compatibility

Well plates follow standardized formats, making them compatible with various automated systems, such as liquid handlers, plate readers, and thermal cyclers. For instance, ANSI/SLAS-compliant plates adhere to specific dimensions, ensuring interoperability between different laboratory instruments.

Core Applications of Well Plates: From Cell Culture to Diagnostics

Cell Culture & Cell-Based Assays

Well plates, especially those treated with tissue culture (TC) coating, are used extensively in cell culture. The plate’s surface treatment allows cells to adhere and grow, making it easier to test various compounds or study cell behavior in a controlled environment.

- Cell Culture: 96-well plates are used to grow cells in small volumes of media, saving time and resources compared to traditional Petri dishes or flasks.

- Cell Viability Assays: Researchers use 96-well plates to perform assays such as the MTT assay to assess cell viability by measuring metabolic activity.

- Drug Screening: Well plates are crucial in high-throughput screening (HTS), where multiple drug candidates or compounds are tested in parallel to assess their effects on cell growth or viability.

The compact nature of well plates allows researchers to test multiple conditions or treatments simultaneously, improving experimental efficiency.

Immunoassays & Protein Detection: ELISA and Related Assays

One of the most common applications of well plates is in immunoassays, specifically ELISA (Enzyme-Linked Immunosorbent Assay), which is used to detect and quantify various biological molecules like proteins, antibodies, and antigens.

- ELISA Assays: Well plates are used to hold samples and reagents in parallel, with each well acting as a separate test tube. The format allows for easy reproducibility and high-throughput screening of proteins or antibodies.

- Fluorescent or Chemiluminescent Detection: The flat-bottomed design of well plates ensures accurate readings when using optical detection systems, such as fluorescence or chemiluminescence.

The use of 96-well plates for ELISA allows researchers to quickly test multiple samples under different conditions, minimizing reagent waste and maximizing experimental throughput.

PCR / qPCR & Nucleic Acid Assays

Well plates are frequently used in PCR (Polymerase Chain Reaction) and qPCR (quantitative PCR) to amplify and analyze DNA or RNA. These processes require precise volume control and consistent heating/cooling cycles, making 96-well PCR plates the go-to choice for most nucleic acid amplification.

- PCR Plates: Well plates made of specialized materials (e.g., polypropylene) are used for PCR because they are compatible with thermal cyclers and have excellent heat distribution.

- Sample Multiplexing: PCR plates allow for simultaneous amplification of multiple samples, making it easier to test several targets in parallel.

With well plates, researchers can perform large-scale genetic analyses, such as gene expression studies or genotyping, in high-throughput. The ability to automate PCR using well plates also helps reduce hands-on time and human error.

High-Throughput Screening (HTS) & Sample Processing

In high-throughput screening (HTS), well plates enable researchers to test large numbers of compounds or biological samples simultaneously. This application is crucial in fields like drug discovery, where testing hundreds or thousands of compounds for biological activity is standard.

- Screening Applications: HTS uses well plates to screen for potential drug candidates, identify biomarkers, or evaluate compounds for toxicity or efficacy.

- Automated Pipetting: Well plates are compatible with automated liquid-handling systems, ensuring high accuracy and efficiency in reagent addition and sample processing.

The versatility and scalability of well plates make them a valuable tool in any laboratory conducting large-scale experiments.

Sample Storage, Preparation & Long-Term Storage / Biobanking

Well plates, particularly deep-well plates, are commonly used for sample storage. These plates can hold larger volumes of liquid, making them ideal for storing biological samples, reagents, or compound libraries.

- Sample Storage: Polypropylene (PP) plates are ideal for long-term storage of biological samples or reagents, especially under freezing conditions.

- Biobanking: Well plates can store large numbers of samples in a controlled manner, making them a cost-effective solution for biobanks and large-scale sample processing.

The ability to store multiple samples in 96-well plates reduces the need for numerous individual containers, streamlining storage and retrieval.

How Labs Choose the Right Well Plate: Factors & Considerations

When selecting the appropriate well plate for an experiment, several factors must be considered to ensure optimal results. These factors include well-bottom shape, material, volume requirements, and compatibility with laboratory equipment.

Well-Bottom Shape and Surface Treatment

- Flat-Bottom Plates: Best for optical measurements such as absorbance, fluorescence, or luminescence.

- Round or V-Bottom Plates: These are designed for centrifugation, mixing, or pellet formation.

- Surface Treatment: Well plates are often treated to enhance cell attachment or protein binding. TC-treated plates are ideal for cell culture, while high-binding plates are preferred for protein assays like ELISA.

Material Choice: Polystyrene vs Polypropylene

- Polystyrene (PS): Offers optical clarity, making it ideal for assays that involve light detection.

- Polypropylene (PP): Chemical-resistant and heat-resistant, making it suitable for long-term storage, chemical handling, and sample preparation.

Volume Requirements

Standard 96-well plates are used for small-volume assays, while deep-well plates are preferred for larger volumes or sample storage.

Compatibility with Lab Equipment

Well plates must be compatible with automated pipetting systems, plate readers, thermal cyclers, and other lab instruments. Be sure to check if your equipment supports the plate type you choose.

Pros and Cons: Strengths & Limitations of Well Plate Use

Well plates have become essential in laboratory work due to their versatility, cost-effectiveness, and compatibility with high-throughput technologies. However, like any laboratory tool, they come with both advantages and limitations depending on the type of experiment or application. Here, we break down the strengths and weaknesses of well plates, specifically 96-well plates, to help you make an informed decision on when and how to use them.

Strengths of Well Plates

- High Throughput and Parallel Processing

- Efficiency: Well plates allow for multiple assays or experiments to be conducted in parallel, increasing throughput and efficiency. For example, a 96-well plate enables the simultaneous processing of 96 samples, which is crucial for applications such as drug discovery, screening, and genetic testing.

- Reduced Labor: Using well plates allows researchers to process large numbers of samples at once, reducing manual labor and saving time. This is particularly advantageous in high-volume research environments like pharmaceutical testing or clinical diagnostics.

- Cost-Effective and Reagent-Saving

- Reagent Conservation: Well plates, especially 96-well plates, are designed for small-volume applications. This feature minimizes reagent usage, making them cost-effective, especially when testing expensive compounds or biological materials.

- Reduced Sample Waste: By working with smaller sample volumes, well plates help conserve precious or limited samples, particularly for rare biological samples or high-cost reagents.

- Compatibility with Automation

- Ease of Automation: Well plates are designed with standardized dimensions, making them compatible with automated liquid handling systems. This enables precise sample preparation, consistent reagent dispensing, and high reproducibility, which are essential in high-throughput environments.

- Integration with Lab Equipment: Well plates can be used seamlessly with plate readers, thermal cyclers, centrifuges, and other laboratory equipment. Their compatibility ensures that experiments are streamlined and data collection is consistent.

- Versatility in Assays

- Wide Range of Applications: Whether you’re working with cell culture, protein assays (like ELISA), genetic tests (PCR), or sample storage, well plates can be adapted for various purposes. Their design supports assays that require optical measurements, mixing, or sample preparation.

- Multiple Plate Types: Depending on the application, well plates come in different variations, flat-bottom for optical assays, round-bottom for mixing or centrifugation, and deep-well plates for storage or large-volume handling.

- Standardization and Ease of Use

- Consistency: The standardized design of well plates ensures consistent results and reproducibility, a key requirement in scientific research. Whether you’re conducting ELISA or PCR, the predictable design of well plates allows for precise experimental setup and consistent data.

- Ready for Multiple Samples: Using well plates, you can easily prepare multiple samples, create dilution series, or run replicates without needing multiple test tubes or flasks.

Limitations of Well Plates

- Volume Constraints

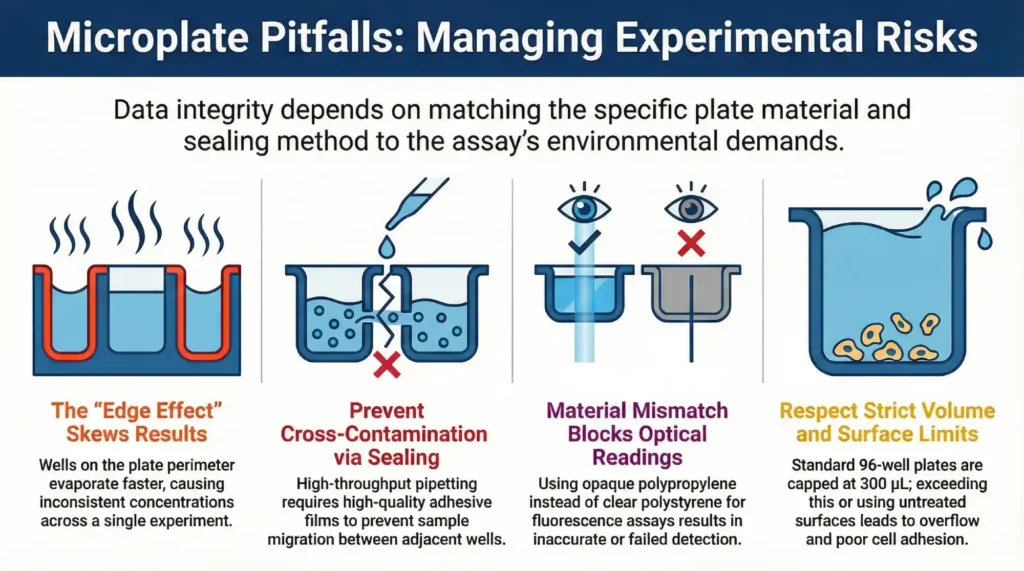

- Limited Volume for Some Applications: Well plates, exceptionally standard 96-well plates, have a restricted volume capacity (generally 100–300 µL per well). While this is ideal for assays that require small volumes, it is insufficient for larger-scale processes, such as bulk reagent handling or large-volume sample processing.

- Not Suitable for Large-Volume Storage: If your experiment requires handling or storing large volumes of liquid, deep-well plates are a better option. While they offer more volume capacity (up to 2 mL per well), the standard 96-well plate may not meet your needs for larger liquid volumes.

- Optical Clarity Challenges for Some Plates

- Limited Optical Clarity: Polystyrene (PS) is ideal for optical assays because it provides excellent clarity for absorbance, fluorescence, or luminescence readings. However, polypropylene (PP), commonly used for deep-well plates, is not as optically transparent. This can create challenges when trying to perform optical measurements in experiments that require accurate readings.

- Surface Treatment Variability: Some well plates may not have the required surface treatment for cell adhesion or protein binding. This means researchers must carefully select the appropriate plates for their specific assays (e.g., TC-treated plates for cell culture or high-binding plates for ELISA).

- Cross-Contamination Risks

- Handling and Pipetting Accuracy: Although well plates are generally efficient and reliable, there is still a risk of cross-contamination if not handled properly. This is especially true in high-throughput environments, where multiple samples are being processed simultaneously.

- Proper Sealing Required: When working with well plates, it is essential to seal the plates properly to prevent evaporation or sample contamination. If plates are not properly sealed, it could compromise the experiment and lead to inaccurate results.

- Evaporation Issues

- Edge Effect: One of the most common challenges when using well plates, particularly in long-term incubations or PCR, is evaporation. The wells on the edges of the plate tend to lose volume more quickly due to increased exposure to air. This is especially problematic when running reactions that require consistent liquid levels throughout the experiment.

- Use of Sealing Films: To mitigate evaporation, researchers often use adhesive sealing films, but this can add an extra step in the workflow. Failure to use proper sealing can lead to inconsistent results or skewed data.

- Incompatibility with Some Assays

- Inappropriate for Certain Optical Assays: For assays that require precise light transmission or clear optical paths (e.g., fluorescence), deep-well plates or plates made from materials such as polypropylene may not be suitable. The material’s opacity can interfere with light detection, making it difficult to obtain accurate results in optical-based assays.

FAQs

What is a well plate/microtiter plate?

A well plate is a flat, multi-well container used to hold liquids for laboratory experiments. The most common format is the 96-well plate, but others, such as 384-well and 1536-well plates, are also used for higher throughput. These plates are used for various assays, including cell culture, PCR, protein detection, and sample storage.

Why do labs use well plates instead of test tubes or petri dishes?

Well plates allow labs to process multiple samples in parallel, saving both time and reagents. With their standardized design, well plates also offer compatibility with automated systems, improving accuracy and throughput compared to using test tubes or petri dishes.

Can I culture cells and run ELISA in the same 96-well plate?

Yes, well plates can be used for both cell culture and ELISA. However, depending on the application, you should choose the correct surface treatment (e.g., TC-treated plates for cell culture and high-binding plates for ELISA).

Which plate material and well-bottom shape should I choose for PCR / ELISA / cell culture?

For PCR, choose polypropylene plates designed for thermal cycling. For ELISA, polystyrene plates with flat bottoms are ideal, as they provide the necessary clarity for optical measurements. For cell culture, choose TC-treated plates with flat-bottom wells for optimal cell adherence.

Are 96-well plates compatible with automated systems and plate readers?

Yes, 96-well plates are designed to be compatible with automated systems and plate readers, making them highly efficient for high-throughput experiments.

Final Thoughts & Recommendations

Well plates, particularly 96-well plates, are indispensable tools in the laboratory. Whether you’re working in cell culture, protein detection, PCR, high-throughput screening, or sample storage, well plates offer unparalleled versatility, efficiency, and cost-effectiveness. The key to successful experimentation is choosing the right plate type for your specific needs, considering factors like material, well-bottom shape, surface treatment, and volume capacity. Always consider the specifics of your assay, equipment compatibility, and the volume of reagents or samples required before selecting the plate type. Feel free to explore more resources or download templates to help organize your well plate choices.